Why it is important to clean all the parts, not just the sensor?

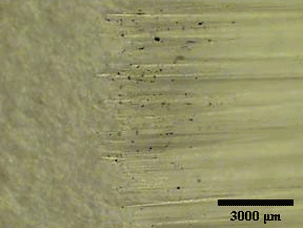

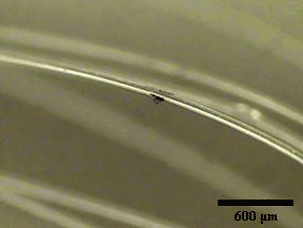

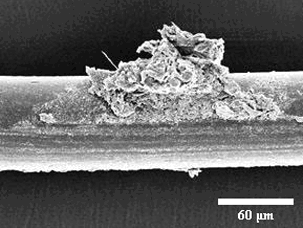

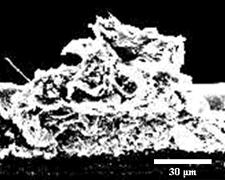

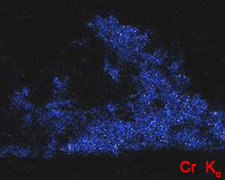

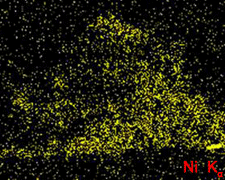

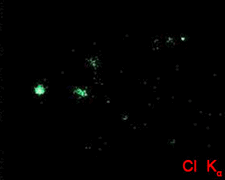

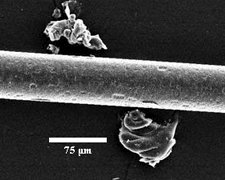

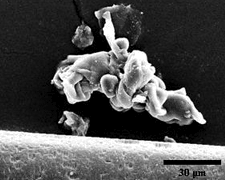

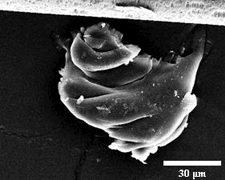

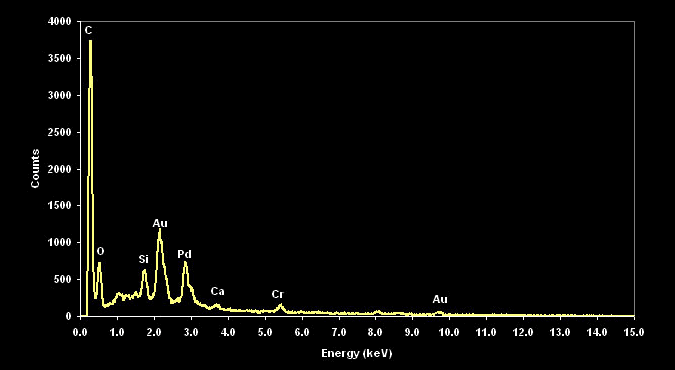

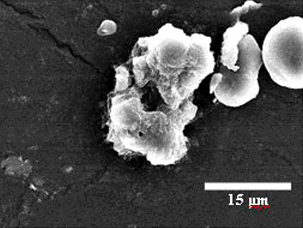

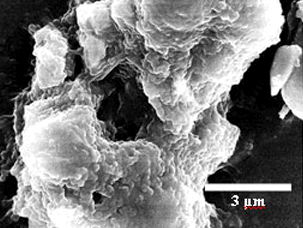

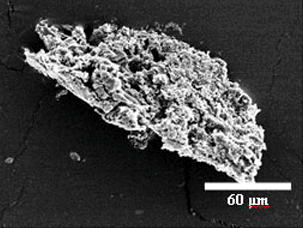

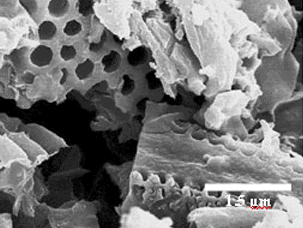

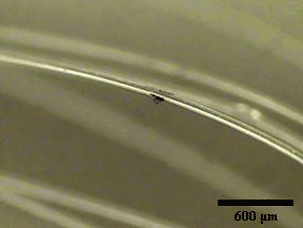

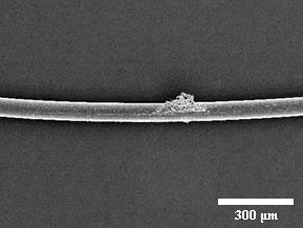

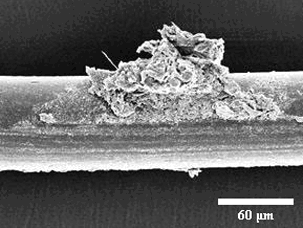

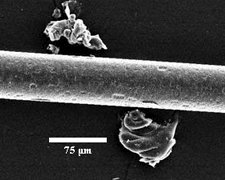

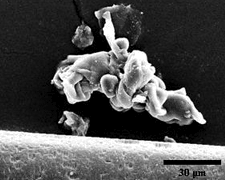

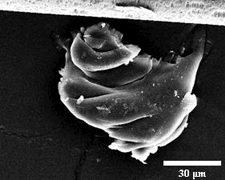

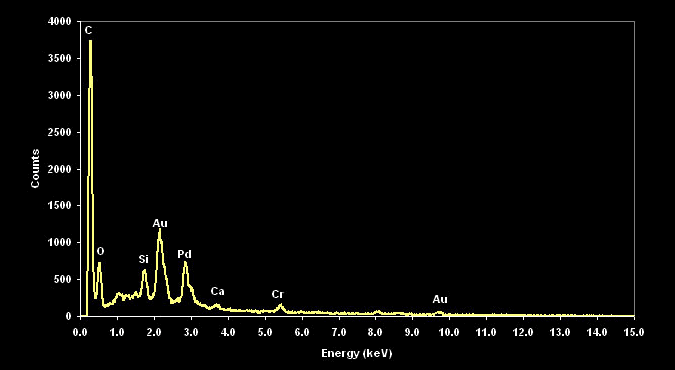

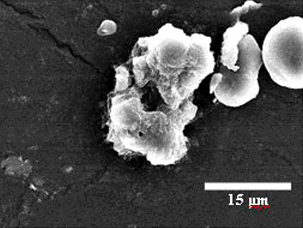

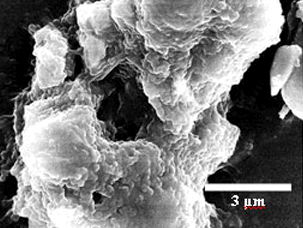

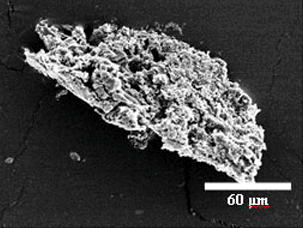

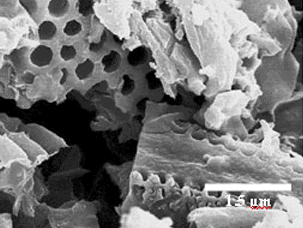

The following images show how the various components of dust are made. By knowing these components one can determine how to eliminate these sources using scientific methods. The samples are taken from the body of the camera and under the metallic O-ring that attaches the lens to the body.

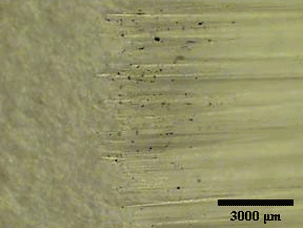

Optical Image 10×

Optical Image 50×

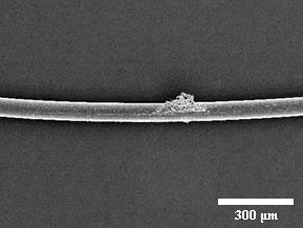

Secondary Electron Image 100×

Secondary Electron Image 500×

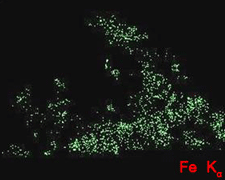

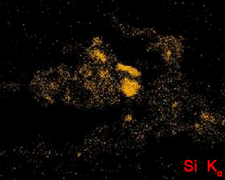

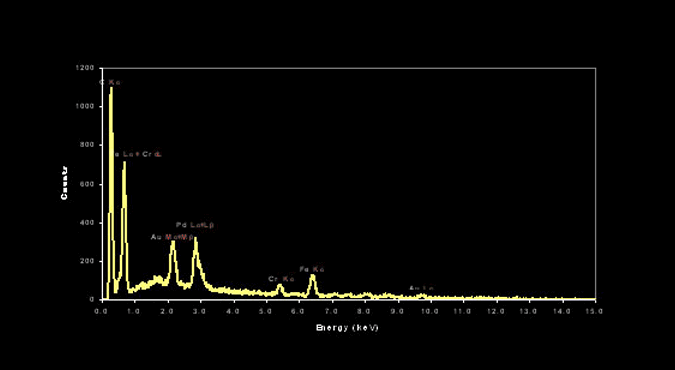

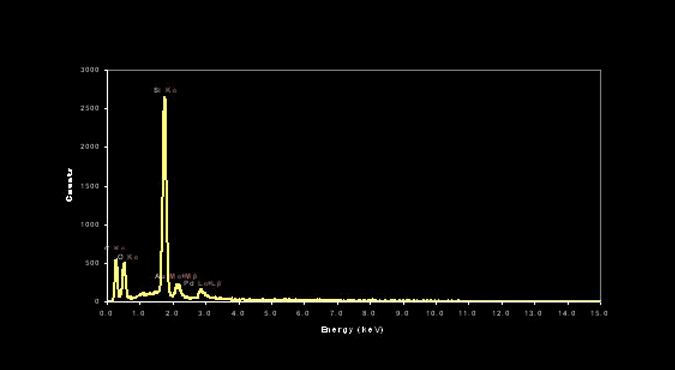

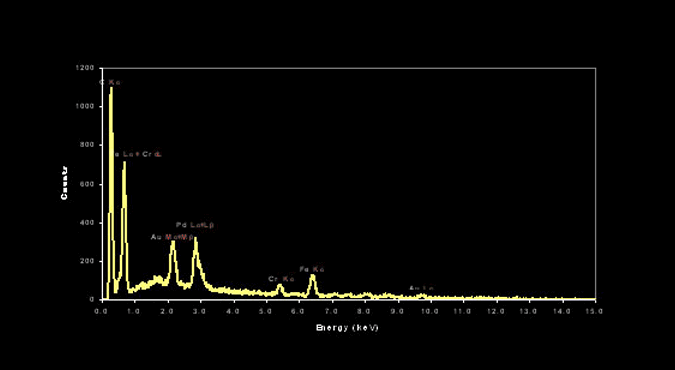

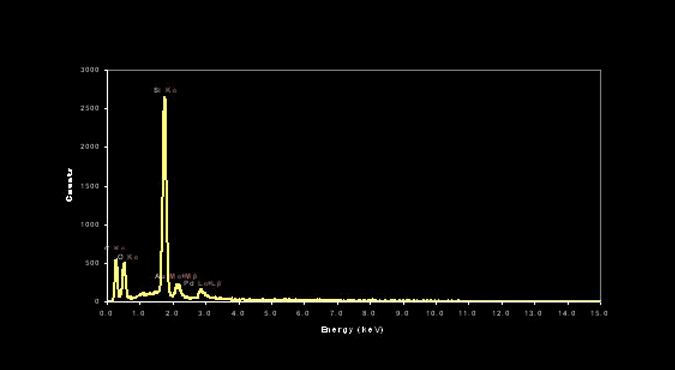

In the following images we can clearly see how the different components such as Si (silicon), Cr, Ni, and Fe are the fabric of this particular dust. The interesting point is that the silicon which is usually the most damaging component due to its hardness is embedded within the core of dust. The other components such as Cr, Ni are coming from the steel that probably originates from the metallic O-ring that attaches the lens to the body. It is not surprising that due to mechanical friction some metallic crumbs are generated that eventually land on the sensor.

Secondary Electron Image 1,000×

Note:

- Au and Pd signals were from Au/Pd thin film,

which was used to improve electronic conductivity of the sample

- Cu and Zn signals were from sample holder, which is made of bronze

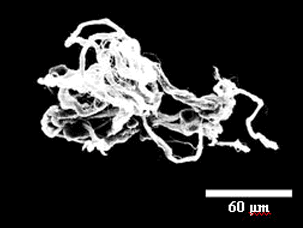

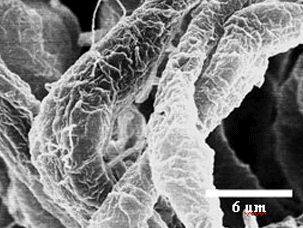

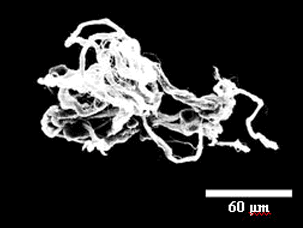

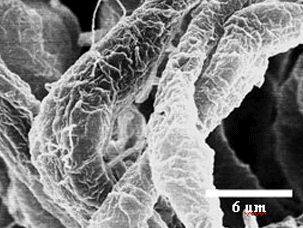

In the following picture which is magnified at 400× and 1000×, one can see how the two particles are hugging the fibers of the Sensor Brush™ filaments in opposite direction. This patented lifting effect due to the charges on the surface can clearly demonstrate the superiority of the Sensor Brush™ as a cleaning tool for removing the dust. Since dust "jumps up" to the fibers, they never have a chance to be dragged across the sensor, which is what would normally happen from a simple sweeping or brushing-off effect.

Secondary Electron Image

400×

Secondary Electron Image

1000×

Secondary Electron Image

1000×

Secondary Electron Image 500×

Secondary Electron Image 5,000×

Note:

- Au and Pd signals were from Au/Pd thin film,

which was used to improve electronic conductivity of the sample

Organic sample:

Secondary Electron Image 2,000×

Secondary Electron Image 5,000×

Note:

- Au and Pd signals were from Au/Pd thin film,

which was used to improve electronic conductivity of the sample

- Cu and Zn signals were from sample holder, which is made of bronze

Man-made sample:

Secondary Electron Image 5000×

Secondary Electron Image 10,000×

Note:

- Au and Pd signals were from Au/Pd thin film,

which was used to improve electronic conductivity of the sample

- Cu and Zn signals were from sample holder, which is made of bronze

Conclusion:

Using a different Sensor Brush® (8mm for example) other than the one used on the sensor will eliminate the risk of smear or contamination of the sensor as seen in these pictures.

These pictures show us that removing these particles from the camera body and chamber area greatly enhances our safety issue therefore preventing dust fall off onto the sensor. This also shows that cleaning the sensor alone is not an effective method.

Remarkably, we are the only company that has a system that eliminates dust from areas other than the sensor!

For more information about Chamber Clean™ and the 8 mm Sensor Brush® visit our sensor cleaning products page.